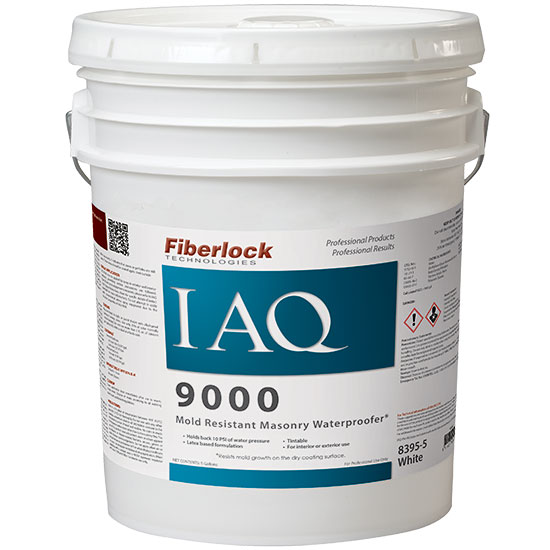

Description

Stop up to 10 psi of water pressure (greater than a wall of water 22 feet high) from penetrating through interior and exterior surfaces with IAQ 9000 waterproofing coating. It’s specially formulated to stop water from above or below grade masonry walls, cinder and concrete blocks, stucco, brick, retaining walls, basements and foundations. The fast-drying formula can be applied with a brush and/or roller on dry surfaces and cleans up easily with soap and water.

How to Use

SURFACE PREPARATION

Surfaces to be coated must be free of dust, mildew, mold, dirt, grease, paint, oil, glue size, calcimine, wax, soap and other surface contamination. Clean mold stained surfaces with IAQ Advanced Peroxide Cleaner, or use an EPA registered antimicrobial disinfectant cleaner such as IAQ 2000, IAQ 2500, ShockWave or ShockWave RTU. Patch irregularities with an appropriate patching compound. Efflorescence, a white, powdery, crystal-like deposit visible on masonry surfaces, must be removed. Muriatic acid, used according to manufacturer’s directions, is an effective efflorescence removal agent.

PRODUCT APPLICATION

STIR THOROUGHLY BEFORE AND DURING APPLICATION. DO NOT THIN. For best results, use a 5 in. paddle wheel mixer, attached to a 1/2 horsepower, 1/2 inch electric drill. Coat surface only when air and surface temperatures are 50˚F or higher. Apply IAQ 9000 directly on bare masonry. For best waterproofing results, wait for a dry (rain-free) period before application. Apply first coat with a good quality nylon bristle brush, working the waterproofer into the pores of the masonry- avoid excessive brushing. Allow to dry 3 hours before second coat. The second coat may be applied using brush, roller or spray. If leaking is still present after two coats, it indicates that pores or pinholes are still open. These areas should be coated again. Vent outside.

SPRAY APPLICATION

IAQ 9000 may be applied by spray to exterior and interior surfaces, providing certain precautions are followed. Special sprayer equipment is required, please refer to IAQ 9000 Spray Instructions sheet for specific details.

TINTING

May be tinted to light or pastel shades with alkali-proof universal tinting colors. Use only 25% of color normally recommended. Do not use more than 2 fl. oz. of colorant per gallon. IAQ 9000 is ideal as a finish coat. If desired, a high quality latex paint can be applied after 24 hours for decorative purposes.

COVERAGE

- Smooth Surfaces: 1st coat – 100-125 sq. ft. per gallon, 2nd coat – 125 sq. ft. per gallon

- Porous Surfaces: 1st coat – 75 sq. ft. per gallon, 2nd coat – 125 sq. ft. per gallon

DRYING TIME

- @ 70°F 50% R.H

- To Touch – 1 hour

- Recoat – 3 hours

CLEANUP

Clean application tools immediately after use in warm, soapy water. Dispose of all waste according to all existing local, state and federal regulations.

PRECAUTIONS

Store in a dry place at temperatures between 40°F (4.5°C) and 90°F (32°C). Stir thoroughly. Do not mix with any other coatings, solvents or colors in oil. IAQ 9000 is resistant to the deteriorating action of mold and mildew. No claim is made for the preservative action other than to the coating film. The use of this product does not protect users or others against food-borne or disease-causing bacteria, viruses, germs or other disease-causing organisms. Do not apply when air or surface temperature is below 50°F or when drying conditions are poor. Use adequate ventilation during application. When applying with a sprayer, wear a NIOSH approved respirator with any R, P, N or HE filter. For interior use only.